What is a Short Circuit What causes one How to Prevent it Circuit Diagram PCB Design Best Practices to Prevent Short Circuits. The foundation of preventing short circuits lies in effective PCB design. Here are some best practices to consider: 1. Maintain Adequate Trace Spacing. Ensure that there is sufficient spacing between traces to accommodate the voltage levels in your design. Following IPC-2221 standards can A short circuit occurs when two points in a circuit that should not be connected come into contact with each other, causing a surge of current that can damage the circuit. For manufacturers, it is important to detect and address these issues early to prevent device failures, protect components, and reduce expensive repairs.

PCB is a crucial part of electronics, and a short circuit can cause severe damage, which could be life-threatening. Addressing the problem of PCB short circuits requires proper maintenance techniques, while the design process precautions prevent future short circuit issues. We can identify short circuits with our naked eyes if the short circuit is between two thick wires; however, in many cases, it is hard to identify short circuits, especially if the wires are so small. In machine-produced PCBs, the wires are tiny, and we need to use more advanced techniques to detect short-circuit failures.

PCB Short Circuit: How to Find and Prevent a Short Circuit on PCB Circuit Diagram

The article delves into PCB short circuits, covering causes, detection, and prevention. It addresses issues like pad design, scratching, and Conductive Anodic Filament formation, offering insights for manufacturing and usage. Methods like visual inspection, thermal imaging, and systematic troubleshooting aid in locating short circuits, ensuring device safety.

Examining the surface of the PCB very closely is the first thing you should do when trying to find short circuits on a PCB. During the examination of the circuit board, you should make use of a magnifying glass or a microscope with a modest magnification if you have access to either of these tools. Short circuits not only affect the performance but can lead to defective products, increased production costs, and rework. This article explores several strategies for effectively preventing short circuits during the SMT PCB assembly process. 1. Component Selection and Inspection. The quality of components is directly linked to short circuit This sort of short circuit can go undetected by the naked eye until the assembled PCBs are put through a series of QC tests. Unfortunately, if a short circuit is detected this late in the production cycle then it is guaranteed to cause unnecessary losses in time and raw material costs. To understand how short circuits happens, you need to

How to Detect and Prevent Short Circuits in PCBs Circuit Diagram

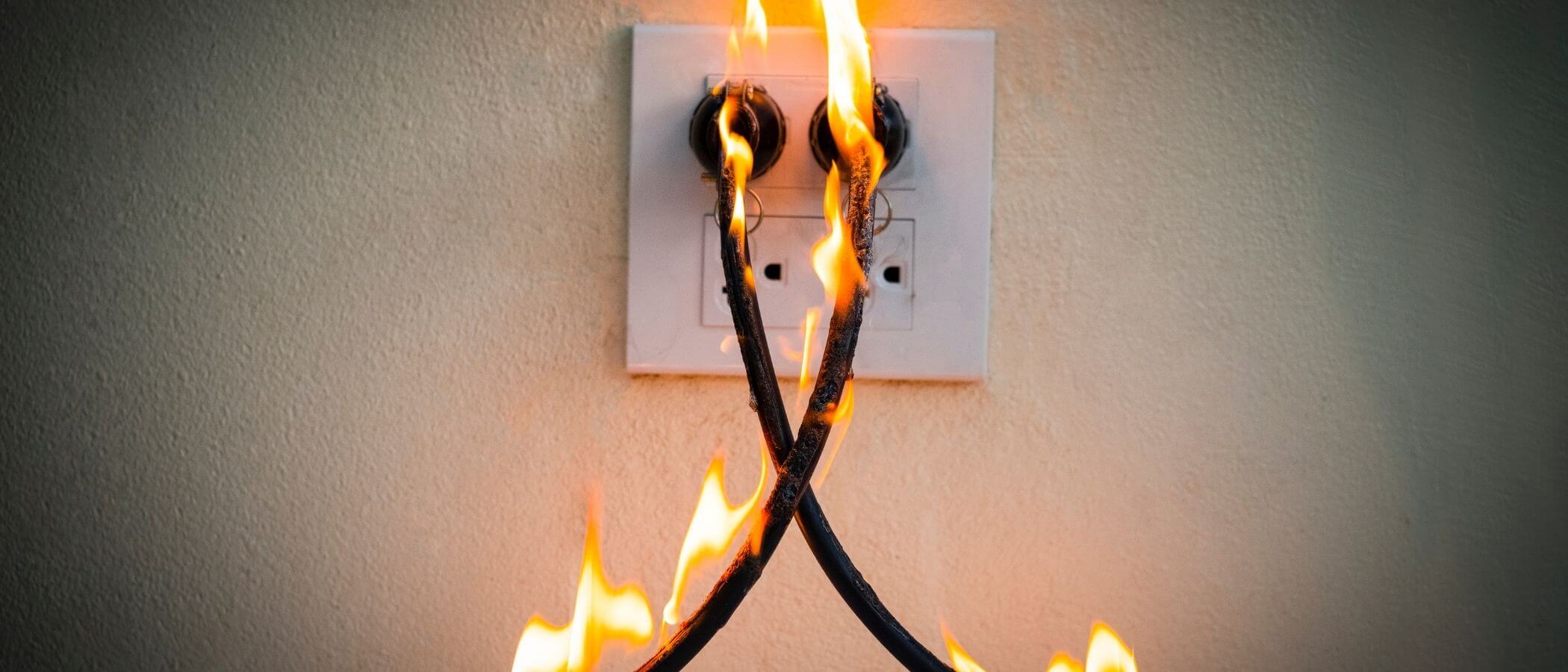

How to Prevent a PCB Short Circuit Preventing short circuits on Printed Circuit Boards (PCBs) is essential for ensuring the reliability and longevity of electronic devices. Here are various preventive measures to minimize the risk of short circuits: 1. Signs of PCB Short Circuits. Recognizing early signs of short circuits can allow diagnostics in due time, to avoid the probable escalations. These include: Burn Marks or Discoloration: The localized overheating caused by a short circuit may leave burn marks or discoloration on the surface of the PCB.