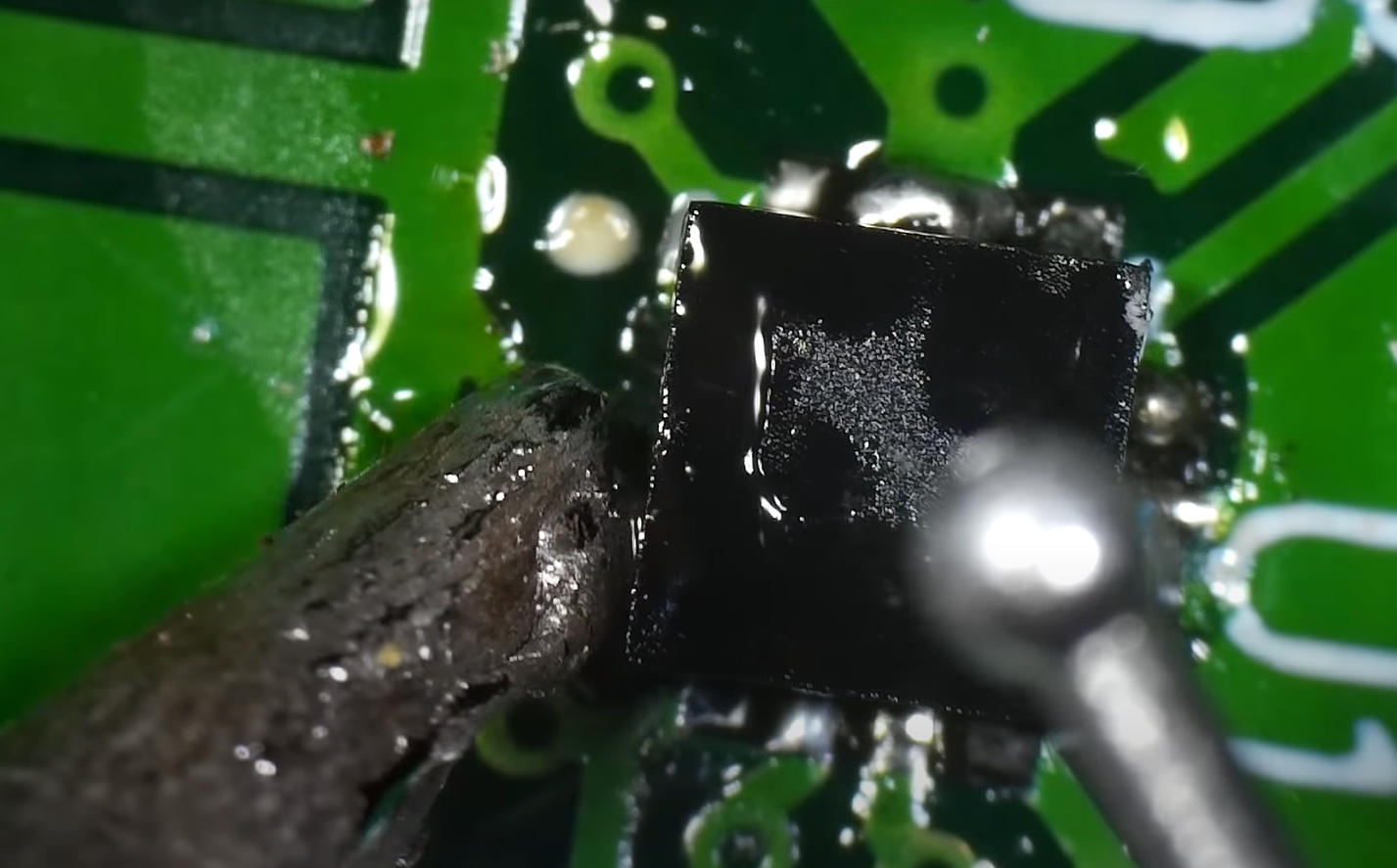

Wave Soldering Vs Reflow Soldering Everything You Need to Know Circuit Diagram It is a well-known fact that hand soldering is a much less controlled process than the SMT process. If it handled correctly, hand soldering could introduce some quality issues. Here are some tips for hand soldering: The solder iron needs to be kept clean. The black crud built up from metal oxide and charred flux should be removed frequently. Reflow soldering, on the other hand, is better suited for SMD-heavy assemblies, providing precise and consistent solder joints with minimal thermal stress on components. When choosing between wave soldering and reflow soldering, consider factors such as component types, production volume, PCB complexity, budget, equipment, and quality requirements.

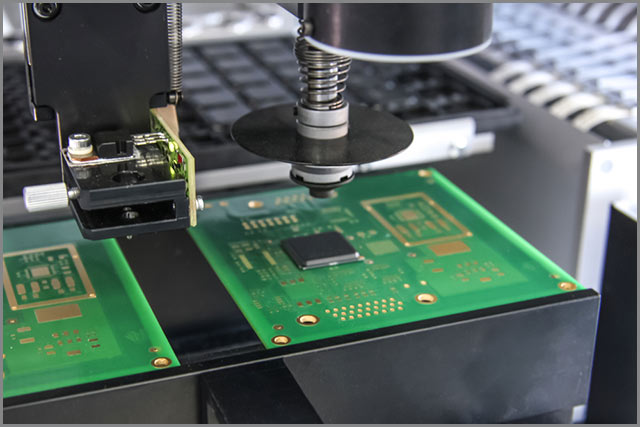

The Procedure of Reflow Soldering. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. Here is a detailed overview of the steps you need to follow in a reflow soldering station. 1. Preparation. The first stage is preparing the board and components for soldering. And wave soldering equipment is more affordable than reflow ovens. Wave Soldering vs. Reflow Soldering: Applications. Wave soldering is ideal for welding through-hole components on circuit boards, while reflow works best for surface mount components. Wrap Up. As you can see, wave and reflow soldering differ immediately from the start.

Wave Soldering vs. Reflow Soldering: What Are The Differences Circuit Diagram

Commercially there are two main soldering methods - reflow and wave. "Manual" soldering may still be used to add selected mechanically complex or large parts but this would be rare. "Manual" soldering could include the use of "robots" for the excessively keen. Wave soldering involves literally passing a wave of molten solder along a carefully

Hand soldering and robotic soldering are used for through hole components while wave soldering and reflow soldering are used for surface mount components. Robotic soldering is now being used to replace the time-consuming hand soldering. Reflow soldering is the commonly used technology for surface mount components which also uses wave soldering. This video shows three different ways we solder electronic components to printed circuit boards: reflow, wave solder, and hand soldering. On the other hand, industrial reflow machines are designed for mass production and can effectively solder a wider variety of components. Wave Soldering vs Reflow Soldering. Wave soldering and reflow soldering are complementary soldering techniques. In the chart below, you will find their main differences: