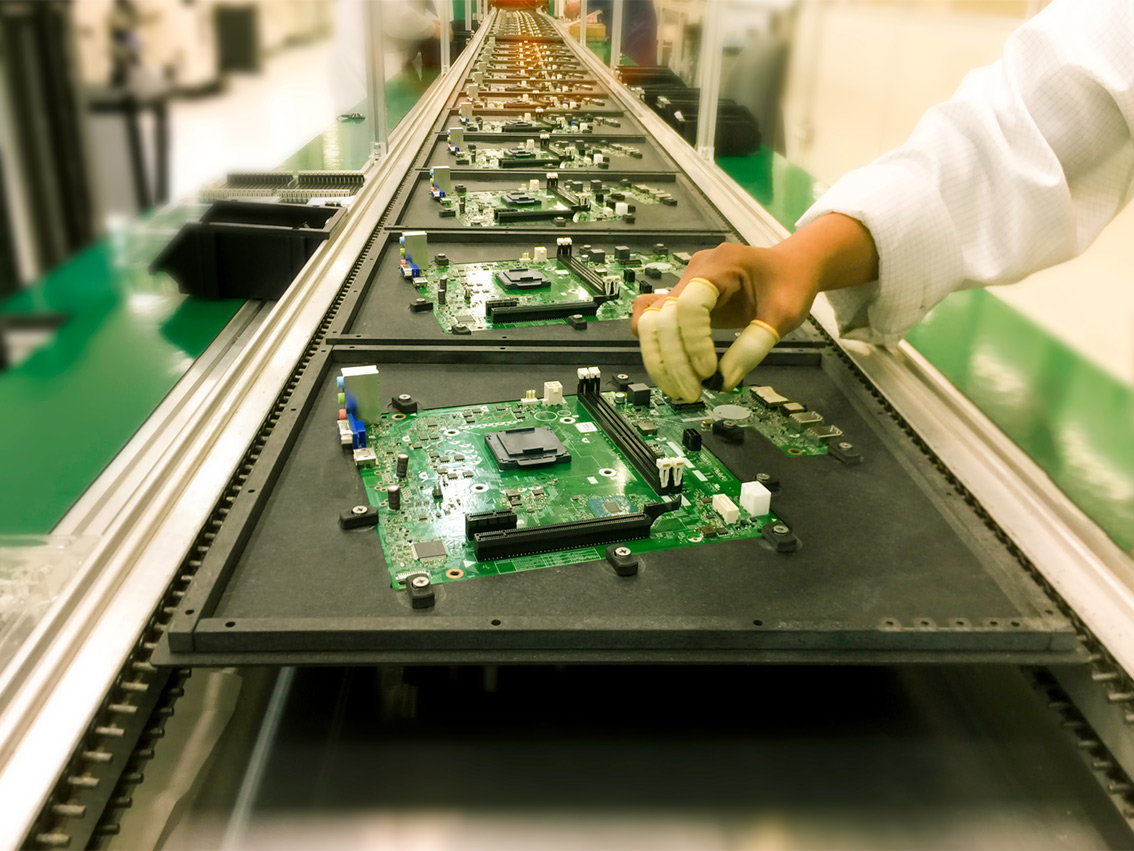

Various Soldering Ways Circuit Diagram The PCB assembly and soldering process completes the physical building of the circuit by picking, placing, and soldering components onto the board. The inspection, testing, and feedback following PCB assembly and soldering make PCB manufacturing a successful process. In this article, we will discuss PCB assembly and soldering processes. Master PCB board soldering with expert DIP process techniques. Learn lead bending, flux application, and defect prevention strategies for industrial-grade reliability. PCB Board Assembly Techniques Explained DIP Soldering Mastery: PCB Board Assembly Techniques Explained. February 21, 2025 February 21, 2025; Why PCB Board Soldering Remains

Explore the essential techniques for assembling and soldering printed circuit boards (PCBs). This category includes comprehensive guides on different soldering methods (wave soldering, hot air solder leveling, hand soldering), tips for effective PCB assembly, and advanced soldering techniques. Articles also address troubleshooting common soldering issues and best practices for achieving Learn about advanced soldering techniques for PCB assembly, including hand soldering, SMT, wave soldering, and more. Explore the latest methods to optimize performance and reliability in electronic manufacturing. 4 Ash Street Extension, Derry, NH 03038 1.855.742.2634 [email protected]

Advance Soldering Techniques for Printed Circuit Board Assembly Circuit Diagram

Mastering PCB Assembly: Unveiling the Art of Soldering Techniques In the realm of electronics manufacturing, Printed Circuit Board (PCB) assembly stands as a pivotal process. At the heart of this intricate procedure lies the art of soldering, a technique that binds components to the PCB, ensuring connectivity and functionality. In…

Here are the different types of PCB soldering techniques: 1. Soft Soldering Harrison has accumulated extensive experience in the R&D and manufacturing of electronic products, focusing on PCB assembly and reliability optimization for consumer electronics, telecommunications equipment, and automotive electronics. Wave Soldering. Wave soldering is utilized for assembly in through-hole processes or surface-mount technology (SMT). It is used for bulk assembly of printed circuit boards. The PCB passes over a pan of molten solder that looks similar to a wave pool (that's where the name comes from). Key Takeaways. When engaging in pcb assembly and soldering, having a clear understanding of essential techniques is crucial for ensuring successful outcomes in your electronic projects. One of the most vital aspects is to consistently implement best practices throughout the process. Such practices include organizing components efficiently, maintaining a clean workspace, and using the correct

Efficient PCB Assembly and Soldering Techniques for Success Circuit Diagram

Advanced Soldering Techniques for PCB Assembly Soft soldering: Soft soldering is the preferred method for attaching small components to a PCB due to its common usage and compatibility with low-liquefying temperature components. To secure these components to the board, a filler metal, typically a tin-lead alloy with a melting temperature Selective soldering: Used when a through-hole component might be damaged by high heat or is unsuitable for the wave and reflow processes; Intrusive soldering: Used to apply solder paste to through-hole components, and solder joints are formed in through-holes during reflow; Automated selective soldering of a PCB's through-hole components.